Product Description

18GA Finish Brad head nails are typically made from 18- or 16-gauge steel wire, which makes them slightly thicker in diameter than regular brad nails. This added thickness gives finishing nails a stronger grip and hold than brads. As a result, finishing nails are often used in applications where a more secure fastening is needed, such as attaching trim or molding to walls or other surfaces. Despite their thicker diameter, the small size and rounded head of the finishing nail still allows for a clean and polished appearance, making them a popular choice for finishing work where appearance is important.

Specification

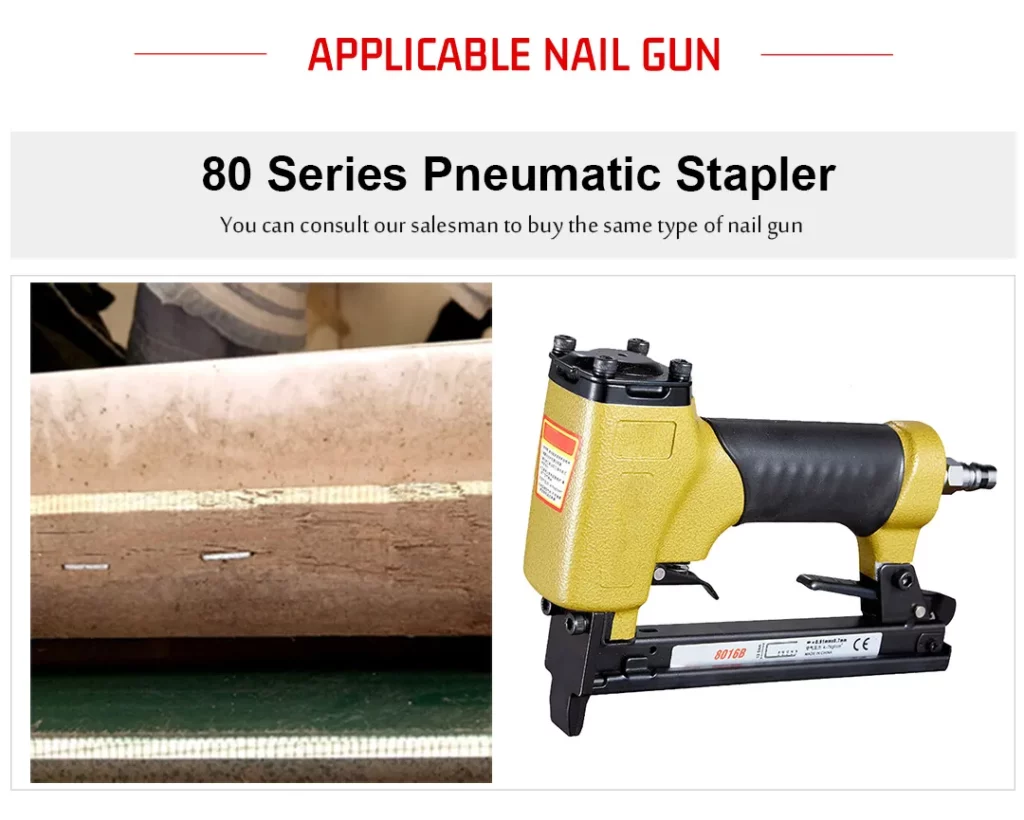

It is crucial to choose the appropriate length of fine wire staple nails for the task at hand to ensure a secure hold without damaging the materials being fastened. If the selected staple is too short, it may not provide adequate holding power, while a staple that is too long could potentially cause damage. Proper selection of staple length is necessary to ensure the success of the project. Furthermore, it is important to pair the fine wire staple nails with a compatible pneumatic staple gun that is specifically designed to work with the chosen staple size.

In contrast to fine wire staples, finishing nails have a small, slightly rounded head that is just a bit larger than the nail shank. They are commonly used in finishing work, such as nailing siding or trim. The small head of a finishing nail allows it to be driven into the surface of the material and then countersunk with a nail set, leaving a small hole that can be easily filled and sanded. This makes finishing nails almost invisible after being driven into the material, leaving little trace behind.

Detail

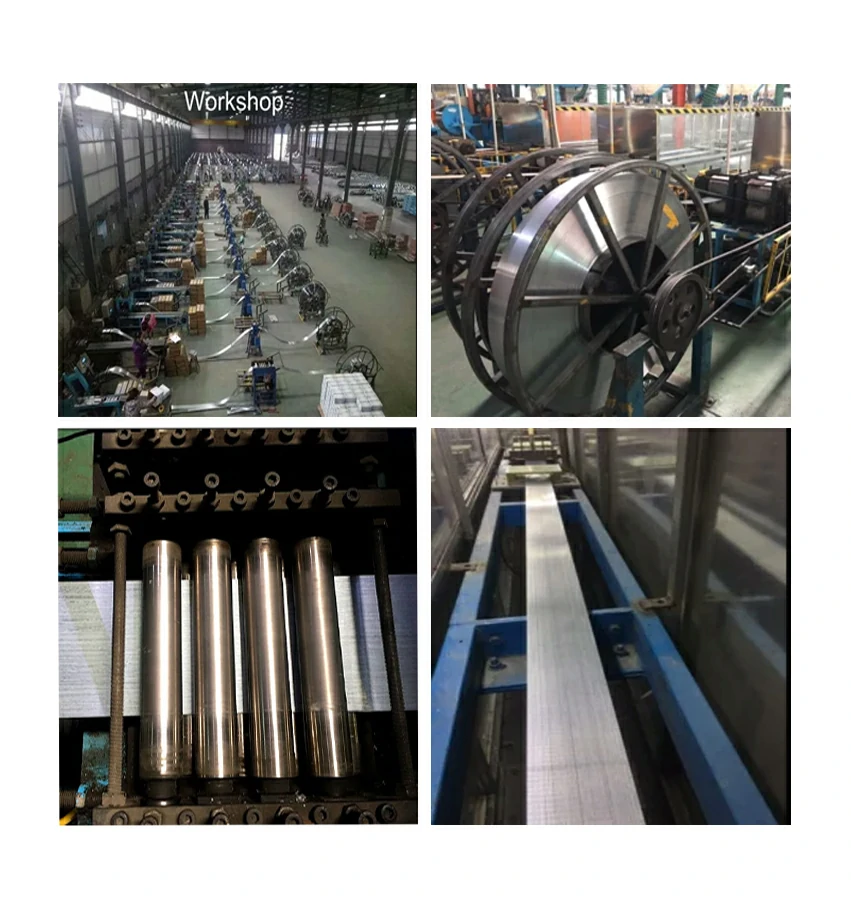

Our production process utilizes high-quality galvanized wire with a minimum of 40g/m2 of galvanization. This ensures that the finished nails are highly resistant to rust and corrosion, providing long-lasting durability and reliability. The use of galvanized wire in our production process allows us to produce nails that can withstand harsh environmental conditions and resist degradation over time. This feature makes our nails an ideal choice for use in outdoor construction projects or in areas with high humidity or moisture levels.

Application

Lighter and subtler, finishing nails are used for trimming such as down jambs, crown moulding, and baseboards.

Applications: Construction

Packing

We can customize the packaging according to customers’ requirements。