Framing Nails

Read To Understand What Framing Nails Are

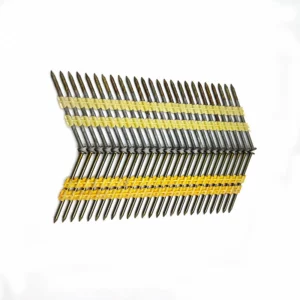

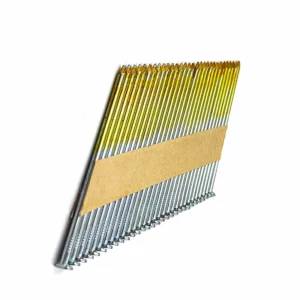

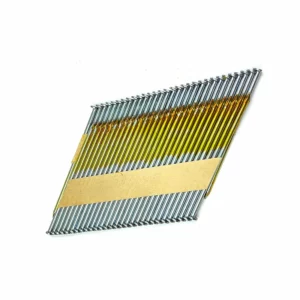

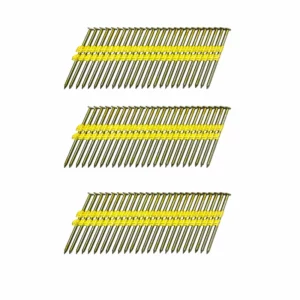

Clipped head framing nails resemble common nails but feature a slightly thinner gauge and more subtle appearance, making them easier to drive flush or sunk into lumber for aesthetics. Their narrower design also enables tighter bends without kinking. Despite their thinner profile, framing nails still offer sufficient strength for their primary purpose: joining lumber to form the framework of structures like buildings. They attach wall studs, floor joists and roof rafters together. Overall, framing nails provide an ideal blend of rigidity, driving ease and durability for most framing applications where a sturdy yet subtle fastener is needed to secure the basic wood framework of a project.

Showing 1–12 of 38 results

-

21 Degree Framing Nails Concrete Nails For Framing

-

34 Degree Nails Paper Collated Framing Nails

-

34 Degree Nails Paper Tape Framing Nails

-

90mm Framing Nails 30 Degree Paper Collated Framing Nails

-

90mm Framing Nails Paper Strip Nail

-

90mm Framing Nails Ring Shank Framing Nails

-

Clipped Head Nails 21 Degree Plastic Collated Framing Nails

-

Clipped Head Nails 34 Degree Collated Nails

-

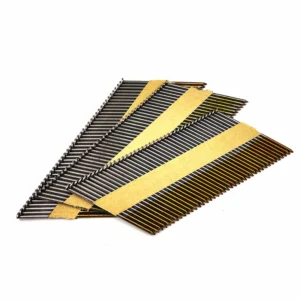

Collated Framing Nails 2 Framing Nails

-

Collated Framing Nails 20 Degree Framing Nails

-

Collated Framing Nails 21 Degree Ring Shank Nails

-

Collated Framing Nails 21 Degree Round Head Framing Nails

Nails share some key traits. They fasten materials like wood or timber. Nails have a long history, used in construction for over 3,000 years. While typically used for wood, nails serve other purposes. Variations in nails’ shapes, sizes and styles fit different uses. Nails come in many types. Nails for heavy-duty use differ from finish nails. Roofing nails contrast with brads. Stainless steel framing nails vary from staples. Each type serves a purpose. Understanding these variations informs which nails work best for a task.

Nail Size Has Two Dimensions – Length And Gauge

Galvanized framing nails length uses the “d” system, with “d” originally representing pennies in Old English. Nail lengths range from about 2 inches (2d) up to around 12 inches (50d).

Nail gauge indicates thickness. Higher gauge numbers indicate thinner nails while lower numbers denote thicker nails.

- 2d – 1 inch

- 3d – 1 1/4 inches

- 4d – 1 1/2 inches

- 5d – 1 3/4 inches

- 6d – 2 inches

- 8d – 2 1/2 inches

- 10d – 3 inches

- 12d – 3 1/4 inches

- 16d – 3 1/2 inches

- 20d – 4 inches

- 30d – 4 1/2 inches

- 40d – 5 inches

- 50d – 5 1/2 inches

The diameter of a nail can be measured using a metric known as the nail gauge. Typically, the higher the gauge number, the thinner the nail. The choice of nail size and gauge will vary depending on the task at hand. As a general guideline, it is recommended to use a nail that is three times longer than the thickness of the material being fastened for optimal results.

Differences Between Flat And Diamond Point Styles For Framing Nails?

Flat point and diamond point framing nails differ in the shape of the tip, which affects how they penetrate and grip the wood:

Flat point nails:

- Have a straight, flat tip

- Provide a broad surface area that helps prevent the nail from splitting the wood as it is driven

- Penetrate wood fibers easily but provide less grip within the wood

- Are suitable for nailing two pieces of lumber at 90 degree angles

Diamond point nails:

- Have a triangular tip shaped like a diamond

- Provide a narrow point that helps the nail grip into the wood fibers

- Penetrate wood fibers with more force but provide more holding power once driven in

- Are suitable for nailing two pieces of lumber at oblique angles or for joining lumber edges

Quality Nail Products From HUAZHEN

Tianjin Huazhen Fastener Co. Ltd was established in 2003. We strive to provide valuable service, high-quality products, and competitive pricing. Our team of over 15 professionals and advanced systems ensure our customers have peace of mind throughout consultation, ordering, procurement, and use of our products.

We maintain a dedicated in-house team to provide considerate service and expert guidance on specifications, material options, and applicable standards. Our technicians carefully inspect every product before shipping to verify quality. Customers can reliably depend on our efficient ordering processes and timely delivery. Hereby, we provide related framing nails below:

Categories