Paper Collated Nails

Concept Of Paper Collated Nails

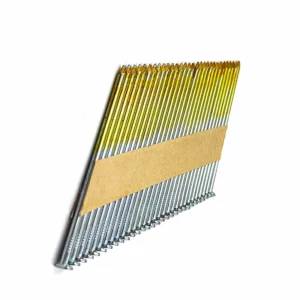

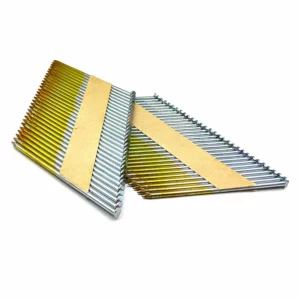

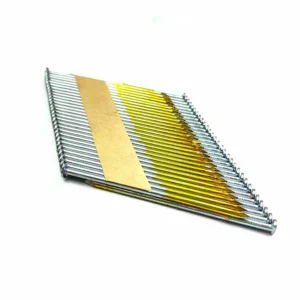

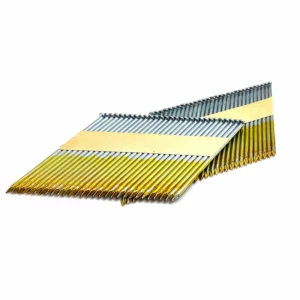

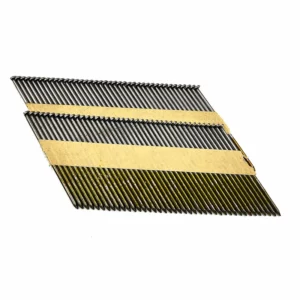

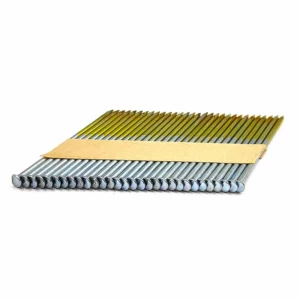

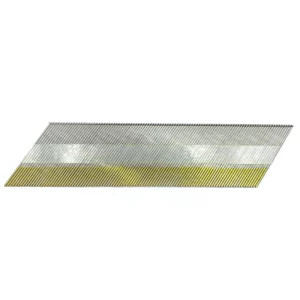

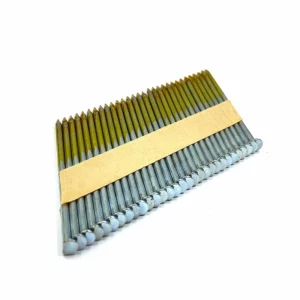

The collated framing nails presented in the paper are specifically crafted to fulfill the factory specifications of 33 degree paper tape nails.

- Carbon steel is the primary material utilized for manufacturing these nails. The production process involves various stages, starting with the straightening and flattening of round wire by a dedicated machine.

- The resulting wire is then gathered on several spools and passed through a gluing machine, where it is coated and dried to create a wire tape.

- Finally, the wire tape is fed into a forming machine, where it is cut, shaped, headed, and completed to achieve the finished product.

Showing 1–12 of 19 results

-

34 Degree Nails Paper Collated Framing Nails

-

34 Degree Nails Paper Tape Framing Nails

-

90mm Framing Nails 30 Degree Paper Collated Framing Nails

-

90mm Framing Nails Paper Strip Nail

-

Clipped Head Nails 34 Degree Collated Nails

-

Collated Framing Nails 30 Degree Ring Shank Nails

-

Collated Framing Nails 33 Degree Nails

-

Collated Framing Nails 34 Degree Clipped Head Framing Nails

-

Collated Framing Nails 90mm Galvanised Framing Nails

-

Collated Framing Nails Clipped Head Framing Nails

-

Galvanized Framing Nails 34 Degree Clipped Head Nails

-

Galvanized Framing Nails 34 Degree Galvanized Framing Nails

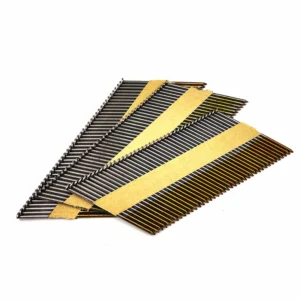

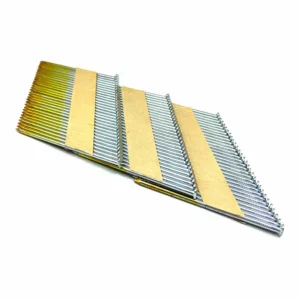

Paper Collated nails, which are fastened together in strips, represent a quick and efficient solution for construction projects large and small. By connecting the nails end to end, collated nails can be fired rapidly from a nail gun. This collated nail system saves time on job sites, helping to reduce labor costs. Whether tackling a minor carpentry task or a major construction project, using collated nails is an effective way to increase productivity. Collated nails are widely used in the construction industry due to their convenience and speed of installation. Collated nail strips are available in a variety of sizes and types to suit different applications and materials.

Paper Collated Nails VS. Plastic Collated Nails

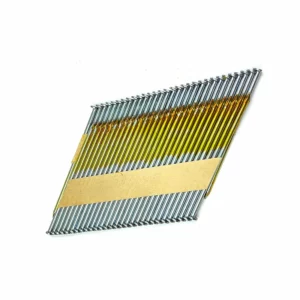

To accommodate a wide range of pneumatic nailer tools, our 34 degree paper collated nails are meticulously engineered to fit all 28° to 34° angles. The collation material we use is made of high-performance and sturdy paper tape, ensuring that the nails remain intact even in varying weather conditions, whether hot, cold, or wet. While paper strip nails are more costly than plastic or wire collated nails, they offer a safer and cleaner driving experience.

Paper Collated Nails’ Specification – By HUAZHEN

With our more than 18 years of experience, HUAZHEN provides customers with one-stop solutions for fastener products. We are willing to cooperate and grow together with our customers. Meanwhile, As leading fastener manufacturer, we provide products such as staple, coil nails and framing nails. Below is related specifictions:

- Diameter – M2.87, M3.05, M3.3, M3.76, M4.1

- Length – 21 to 120mm

- Degree – 28°, 30°, 34°

- Material – Q195, Q235

- Shank – Smooth, ring, twisted

- Head – Clipped D head, round head, offset round head

- Finish – Polish, paint coated, Zinc plating, hot dip galvanized (HDG)

Hereby As popular products Recommandation:

Categories