In the intricate world of construction and woodworking, the selection of the right fastening solutions can make all the difference between a structurally sound build and one prone to vulnerabilities. Among the many options available, 21 degree framing nails, especially those treated with galvanization, stand out as a popular and reliable choice. Today, we delve into the specifics of these nails, exploring why they are favored by professionals worldwide, and how HUAZHEN, a renowned China stainless steel framing nails factory, meticulously crafts these essential components to meet the highest industry standards.

Understanding 21 Degree Framing Nails: The Angle Matters

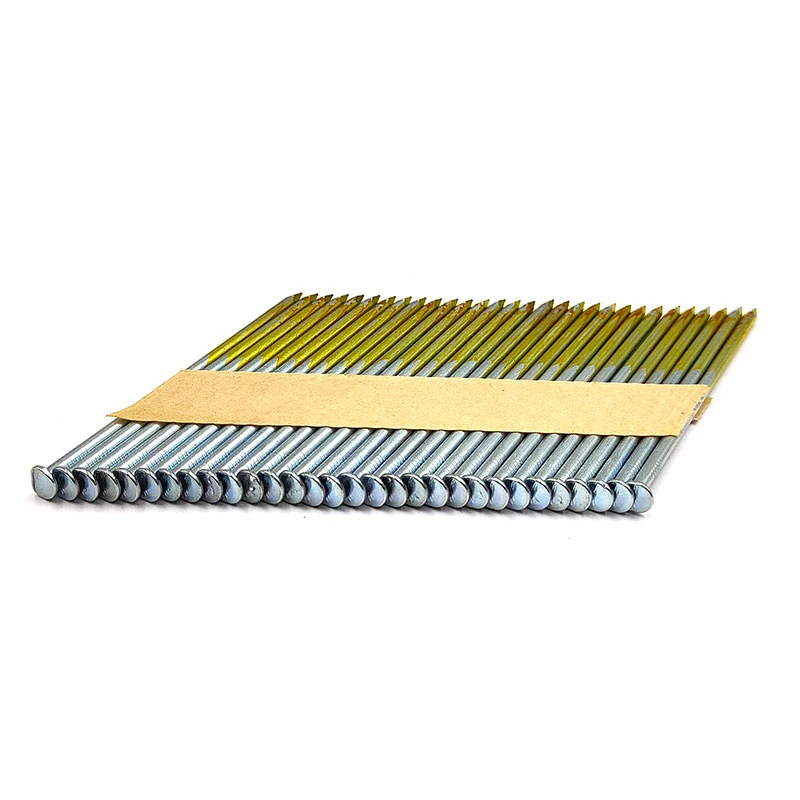

Framing nails come in various configurations, each designed to work optimally with specific nail guns. The angle refers to the collation of the nails in the strip, which directly influences the type of nailer they are compatible with. The 21-degree angle is a widely used format in the industry, designed for use in high-powered framing nailers. This angle ensures that the nails are driven straight and deep into the wood, providing superior holding power while minimizing the risk of bending or buckling under pressure.

Galvanized Treatment: Shielding Against the Elements

One of the defining features of HUAZHEN’s 21 degree framing nails is their galvanized treatment. Galvanization is a process where a protective zinc coating is applied to the nails, forming a barrier against corrosion and rust. This is particularly crucial in outdoor applications and humid environments where moisture can rapidly degrade untreated metal, compromising the integrity of the structure. Galvanized nails offer extended durability and weather resistance, ensuring that the fasteners maintain their strength and appearance for years to come.

Types of Galvanization: Hot-Dip vs. Electroplating

At HUAZHEN, we offer two primary methods of galvanization to cater to different project requirements:

Hot-Dip Galvanizing: This process involves immersing clean nails into a bath of molten zinc. The resulting coating is thick and robust, providing an extra layer of protection against corrosive elements. Hot-dip galvanized nails are ideal for heavy-duty applications or projects exposed to severe weather conditions, where maximum corrosion resistance is vital.

Electroplating (Zinc Plating): A more streamlined method, electroplating deposits a thin layer of zinc onto the nails through an electric current. This technique yields a smooth, aesthetically pleasing finish that is perfect for indoor projects or those with less exposure to harsh elements. While the coating is thinner than hot-dip galvanizing, it still provides ample protection for most standard applications.

Why Choose HUAZHEN for Your Galvanized Framing Nails?

HUAZHEN’s reputation as a leading stainless steel framing nails factory in China is built upon a commitment to quality, innovation, and customer satisfaction. Our 21 degree galvanized framing nails embody this philosophy, showcasing the following advantages:

Precision Manufacturing: Utilizing state-of-the-art machinery and rigorous quality control measures, we ensure that every nail meets exacting standards for consistency and performance. This translates to nails that drive smoothly, reduce jams, and provide reliable holding power.

Customization Options: Recognizing the diverse needs of our clients, we offer a range of lengths, shank diameters, and head styles to suit various applications. Whether you’re framing a house, constructing a deck, or repairing fencing, we have the right nails for the job.

Environmentally Conscious Production: We prioritize sustainable practices in our manufacturing processes, minimizing waste and using eco-friendly materials wherever possible. Our goal is to provide durable, high-quality nails without compromising the environment.

Competitive Pricing and Prompt Delivery: Leveraging our efficient production lines and strong supply chain management, we are able to offer competitive pricing without sacrificing quality. We understand the importance of timely delivery in construction projects, and therefore strive to fulfill orders promptly.

Conclusion: Building Trust, One Nail at a Time

In conclusion, 21 degree galvanized framing nails are a staple in modern construction due to their superior holding power, versatility, and long-lasting corrosion resistance. HUAZHEN, as a trusted name in the industry, takes pride in producing nails that not only meet but exceed industry expectations. Our commitment to excellence in manufacturing, customization, environmental responsibility, and customer service sets us apart, making us the go-to choice for professionals seeking reliable, high-performance fastening solutions. When it comes to building structures that stand the test of time, trust HUAZHEN’s 21 degree galvanized framing nails to be the unseen heroes holding.