Within the vibrant realm of construction, each fastening element assumes a pivotal function in upholding structural robustness, durability, and fortitude. Amidst the array of choices at hand, three distinguished stalwarts emerge as the cornerstone of global construction endeavors: galvanized framing nails, 34 degree nails, and plastic collated nails. These formidable companions not only streamline the construction procedures but also elevate endurance, effectiveness, and security.

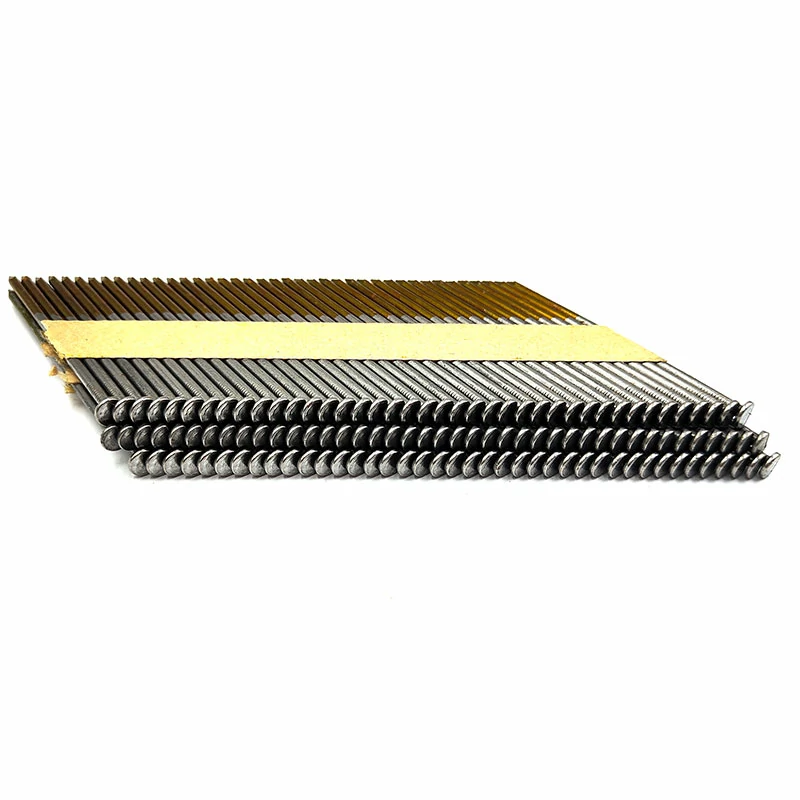

Galvanized Framing Nails: The Guardians of Durability

We ensure that our Galvanized framing nails are made from high-quality wire and undergo surface treatments such as vinyl coating and galvanization to resist rust and corrosion. Our nails are well-designed for safe use with all brands of nailer guns, thanks to our extensive industry experience.

The galvanization process involves immersing the nails in molten zinc, creating a bond that is virtually impervious to rust and corrosion. This ensures that Galvanized Framing Nails maintain their integrity and strength, even in high-moisture and corrosive environments. From coastal regions prone to saltwater exposure to industrial settings with aggressive chemicals, these fasteners offer peace of mind, knowing that structures are fortified against the ravages of corrosion, year after year.

These nails are commonly used in outdoor construction, framing, decking, and other applications where exposure to the elements is a concern. Here are some key features of galvanized framing nails:

- Corrosion Resistance: The galvanized layer bestows exceptional shield against oxidation and erosion, guaranteeing enduring resilience in demanding surroundings.

- Exceptional Strength: Galvanized framing nails are crafted to deliver formidable gripping force, rendering them perfect for robust framework and architectural uses.

- Adaptability: These nails are compatible with an array of wood species and substances, presenting adaptability in projects of diverse magnitudes within the realm of construction.

34 Degree Nails: The Versatile Workhorses

34 degree nails refer to the angle at which the nails are collated in the strip or coil.In the realm of construction, versatility is key, and 34 degree nails exemplify this trait with finesse. Their unique angled design allows for access to tight spaces and awkward angles, making them ideal for applications where traditional straight nails fall short. Whether it’s framing, siding, or roofing, 34 degree nails deliver unmatched performance, driving effortlessly through various materials with precision and efficiency.Here are the advantages of 34 degree nails:

- Increased Holding Power: The angled design of 34 degree nails allows for better penetration and holding power, making them suitable for demanding construction tasks.

- Efficient Installation: The collation angle enables efficient nail placement, especially in tight spaces or when using nail guns, improving productivity on the job site.

- Compatibility: 34 degree nails are compatible with a wide range of nail guns and pneumatic tools, offering versatility in construction applications.

Plastic Collated Nails: The Pinnacle of Efficiency

Plastic collated nails are fasteners that are held together with plastic strips or coils for easy loading and feeding into nail guns. Efficiency is the cornerstone of successful construction projects, and Plastic Collated Nails embody this principle flawlessly. Their plastic collation not only enhances durability but also facilitates rapid loading and feeding, minimizing downtime and maximizing productivity on the job site. Whether it’s framing, trim work, or finish carpentry, Plastic Collated Nails offer unparalleled speed and convenience, allowing contractors to work faster without sacrificing quality or precision:

- Jam-Free Operation: The plastic collation minimizes the risk of jamming in nail guns, ensuring smooth and uninterrupted operation on the job site.

- Reduced Recoil: Plastic collated nails exhibit reduced recoil compared to wire-collated nails, enhancing user comfort and control during nail gun use.

- Enhanced Durability: The plastic collation adds an extra layer of protection to the nails, preventing moisture absorption and maintaining nail integrity over time.

The Triumvirate of Construction Fasteners

Individually, Galvanized Framing Nails, 34-Degree Nails, and Plastic Collated Nails are formidable assets in the construction arsenal. Together, they form a triumvirate of unparalleled strength, versatility, and efficiency, driving progress and innovation in the construction industry. From the foundation to the finishing touches, these fasteners play a pivotal role in shaping the built environment, ensuring safety, durability, and longevity for generations to come.

Building a Better Future with Quality Fasteners

Within the perpetually advancing domain of construction, the selection of fastening elements assumes a crucial position in shaping the robustness, longevity, and effectiveness of edifices. Galvanized Framing Nails, 34-Degree Nails, and Plastic Collated Nails epitomize the virtues of superior workmanship and ingenuity, furnishing the dependability and functionality essential for surmounting the most formidable construction obstacles. Opting for these adaptable and trustworthy fastening components empowers contractors and constructors to erect foundations of unprecedented strength, guaranteeing that the architectural wonders they craft endure through time and withstand the rigors of nature across generations.